B5 Passat Rear Door Lock Mechanism Repair

Here is my write-up on fixing an intermittent REAR door lock. The majority of the credit goes to taligentx website and his write-up on fixing the front door lock mechanism. I’d suggest reading his full write-up, and then comparing the two.

http://www.taligentx.com/passat/maintenance/doorlockmechanism/

This procedure is modeled (and partially copied) from taligentx’s instructions. My intent is to bring together all the steps into one clear set of links and instructions. Where the procedures differ only slightly or I’ve put in additional details, it is in bold/red. Other areas are completely different instructions (as noted). I've included pics mostly for those areas not covered in, or different than, taligentx's instructions.

START BY REMOVING THE DOOR PANEL

To start, use this great write-up by captainfantastic to remove the rear door panel:

http://www.passatworld.com/forums/showthread.php?t=263981

I used this write-up, with diagrams, by VAGGuy, to verify the procedure:

http://www.passatworld.com/forums/showthread.php?t=305767

My notes on these steps:

1. The handle cover is attached by three clips. As mentioned in this write-up, it takes quite a bit of force to pry it off (more than I expected). I could easily see this piece breaking if a lot of care is not taken. And please make special care not to damage the upholstery. Put something behind the screw driver or simply pull away rather than leveraging against the upholstery.

2. I did not have a panel separator tool. And I’m guessing 99% of the people who attempt this don’t have one either. I wanted to minimize the chance of breaking the plastic retaining clips. To start, I used a thin flathead screwdriver to slightly pull back a portion of the door panel, and then inserted a puddy knife through the opening. Then I inserted the screwdriver behind the puddy knife (on the metal side) to give it support. I leveraged both and it was very effective at safely separating the clips from the door panel. (picture pending)

3. I found it easier to disconnect the puddle light at the base of the door before disconnecting the cable and window/door electrical harness. It gives you more freedom/access to get the door panel away from the door.

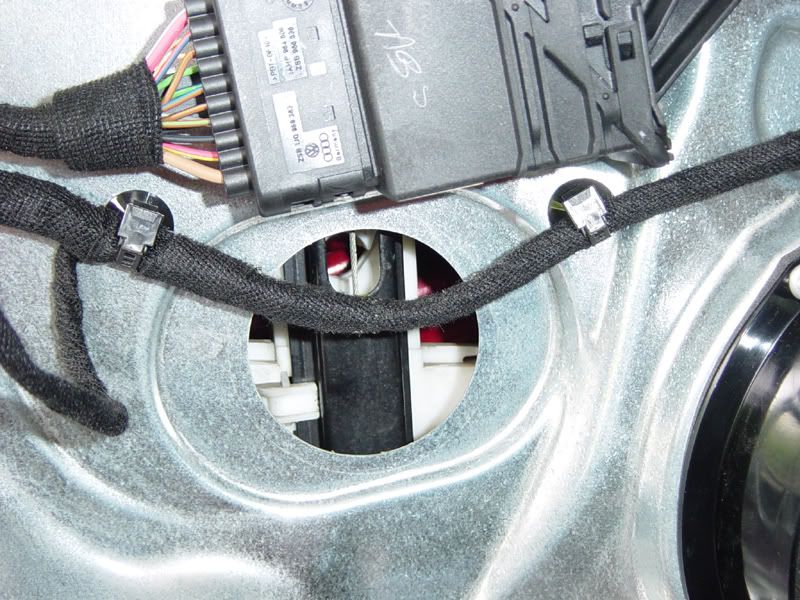

Here is what the door looks like behind the door panel:

![Image]()

WINDOW GLASS REMOVAL

The window removal for the rear door is totally different than the front door. Instead of bolts with retaining clips, there is one plastic retaining “donut”.

1. There is one large rubber circular insert on the metal panel. Remove this. (If you pry with a screwdriver, take care not to damage the mating surfaces.) There is a metal bar behind the hole that has its own access hole.

![Image]()

2. You may need to slightly roll up the window until you can see a donut-like plastic white pin (window retaining pin) through the metal bar access hole. Turn the car key to the On position, and use the driver’s door switch to slowly more up the rear door window. It helps to have a second set of eyes here. (picture pending)

3. Now that you can see the white plastic window retaining pin, you need to pop it out of the window cutout hole. I believe the formal procedure says to first push out the inner plastic tension pin (as confirmed by Steve_In_Chicago), then the larger outer pin. The inner pin expands the outer pin to hold it in place. Use a blunt instrument slightly smaller than the width of the plastic tension pin. Push aside the metal wire for access. Lightly hammer the tension pin to push it out. Be very careful that the hammering instrument doesn't come too close to the sides as it may impact the glass. Also be very careful not to hit the pin too hard and drive it into the outer door (and dent it). Once the inner pin is out, you can push out the outer pin. They will fall down to the bottom of the door. You can retrieve them later when you pull the metal panel off. (In my case, both inner and outer pins were dislodged as one unit.)

This is the pic after the pin has been pushed out:

![Image]()

4. With the plastic pin out, the window will freely move. Carefully slide it up all the way (full up position), and tape it around the top of the door frame (picture pending). I used gorilla tape, but duct tape will probably work just fine. Be careful to protect the top of your door (paint, etc) by putting something like a plastic bag or paper towels between the tape and the non-glass areas. This is another spot where a second set of hands is useful – can’t be too careful with the glass.

UNHOOKING THE LOCK MECHANISM

Note: very similar to front door, except the position of the lock set screw.

1. Pull back the weather trim on the side of the door to expose the lock set screw.

![Image]()

2. Use a Torx T20 driver to partially unscrew the set screw (a few turns at a time). Pull on the exterior door handle - with the door handle in this position, pull on the lock cylinder trim. Keep on unscrewing and testing until the lock cylinder trim loosens and can be removed. NOTE: It is important not to completely unscrew the set screw so as to keep the mounting hardware (behind the door) from falling into the door.

Here is taligentx's pic (note there is only trim, no lock, on the rear door) for this step.

http://www.taligentx.com/passat/images/photo.php?photo=337&exhibition=4&pass=public&lang=eng

3. After removing the lock cylinder trim, you will notice a cable hooked into the side of the exterior door handle. The cable can be positioned (clipped-in) at various points along the handle. Mark the current position by taking a sharpie marker and marking the receptacle (socket) at the end of the cable. Then, prop it loose with a small screwdriver, releasing it from the handle.

![Image]()

![Image]()

4. Use the M8 12 point star driver to remove the two screws, in the door side, that are holding the entire lock mechanism.

![Image]()

REMOVING THE METAL PANEL

1. Disconnect the various wire harnesses on the metal door panel - don't worry about what goes where - each connector can only fit in one and only one place. (picture pending)

![Image]()

![Image]()

2. Use a flathead screwdriver to unclip the various snaps holding the wiring to the panel. It is very easy to break these clips. They may also be brittle from age and heat. I would recommend slightly propping them up with one screwdriver, and using a second screwdriver to try to push in the tabs holding the clips into the metal. Most of my clips broke. To fix them, I bought some generic panel holders and used them with zip-ties to secure the wire harnesses. If you need to replace, try to ensure the new clips are mostly waterproof by using a gasket, sealant or similar. (picture pending)

IMPORTANT ALTERNATIVE OPTION (Thanks Steve_In_Chicago): The black plastic harness holders can be removed without damaging them if you unbolt the metal panel and can get a hand behind it. Use a pliers to squeeze together the little arms holding it into the hole. If you get them squeezed just right, they'll pass through the hole undamaged. Expect to scrape up your arms.

![Image]()

![Image]()

3. Use the 10mm socket to unscrew the seven hex bolts securing the metal panel to the door frame.

![Image]()

4. Pull the panel away from the door frame starting at the edges - if you haven't removed the panel before, the gasket may require a lot of force to pry it away from the frame. Be careful, because the metal can be easily dented by leveraging a screwdriver. Once I finally got a corner of the metal plate starting to separate, my gasket started to pull away from portions of the metal (and stick to the door frame). I used my finger to release the gasket from the door frame and keep it all attached to the metal frame.

5. With the gasket fully separated, the metal panel should be loose. Carefully pull the metal panel down and to the right to allow the attached locking mechanism to clear its corner. Take your time and slowly work it out. Maneuver the entire panel around until the panel is free of the door frame with the lock mechanism and associated wiring attached.

6. Remove the wire harness from the lock mechanism, and push out the rubber gasket (in the metal panel) through which the lock mechanism wire goes through. Pull the wire through the metal panel and remove it - this will allow you to completely separate the metal panel from the door.

REMOVING THE LOCK MECHANISM

1. The lock mechanism is held in place on the metal panel by a plastic bracket with two cylindrical pins keeping the bracket in place.

![Image]()

2. Use a blunt tool to push the pins out from the rear of the panel. (I used the star driver tool as it was just the right size.) My Passat had managed to work the pins loose and dropped them into the door frame, where they've likely lain for months. The bracket had then worked loose of the panel and the entire lock mechanism was free to jostle around in the door. The wiring harness, still being pinned in place, then stressed the electrical connectors internal to the lock mechanism and cracked a solder joint.

![Image]()

3. Unhook the door lock pin rod from the lock mechanism. This may require twisting/spinning the entire lock mechanism to get the best angle to rotate the end of the rod out of the retainer. You will be restricted by the release handle cable. Take your time and avoid rushing and breaking the plastic retainer. (illustration)

![Image]()

4. Remove the interior door release handle cable. Start by popping the harness out of the mount on the locking mechanism. The harness is very securely mounted. I had to use a small screwdriver and leverage from a small gap below the mount to get it to pop out. After releasing the harness, unhook the cable. The cable has to be turned 90 degrees to clear the hole.

5. Separate the locking mechanism from the panel.

LOCK MECHANISM DISASSEMBLY

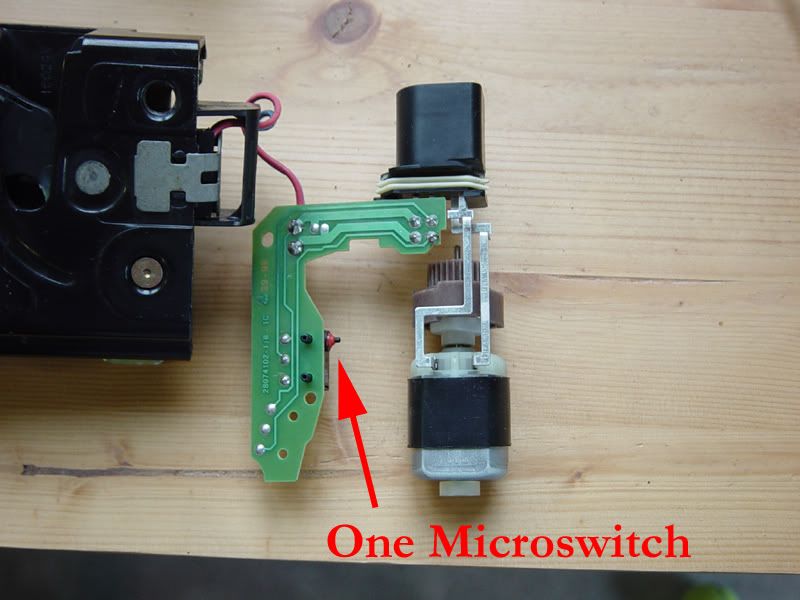

Note: The lock mechanism repair procedure/description is the same as the front door, except for only one microswitch on the circuit board itself. Follow taligentx’s instructions. I’ve edited/annotated a few areas (in bold).

1. Use a Torx T10 driver to unscrew the 5 visible Torx screws (four on the face, one on the side). (illustration)

2. Pull the plastic bracket's long clip from the mechanism - there is a sixth screw hidden underneath.

3. Use a Torx T20 to remove the large Torx screw.

4. You should now be able to carefully pull apart the two sections of the mechanism - you'll need to unclip the plastic snaps while pulling the sections away from each other. (illustration)

5. After pulling these sections away, the last Torx T10 screw will be revealed. Remove it.

6. Flip the mechanism to the yellow plastic side. Pull and remove the spring indicated. NOTE: Be sure to note the orientation of this spring. (illustration)

7. Pull the metal handle indicated upward to allow separation of the two halves.

8. Flip to the black plastic side without allowing the two halves to separate.

9. The internals of the mechanism are mounted on the yellow plastic half - carefully pull up on the black plastic half to reveal the electronics inside. (illustration)

Locking Mechanism Diagnosis:

The electronics are straightforward. There is only one microswitch for the rear door. This microswitch, next to the white plastic slide, determines the current state of the door lock. The motor actuates electronic locking and unlocking.

![Image]()

Note: Take care not to change the position of the various handles and slides - it's fairly easy to determine how the different switches and handles interact with each other when it's time to put things back together, but it's easier to leave everything in the positions discovered. Also, note the position of the brown gear on the motor shaft to the small white attachment mounted inside. To be safe, I used a sharpie marker to mark the positions of the wheels (relative to each other) and the position of the white plastic slide (relative to the housing). There is an alignment between the notch in the copper track inside the brown gear and a metal cylinder in the white plastic container. Just be sure to reset this relationship during reassembly.

10. Pull the white slide from the assembly, along with the white mount holding the shaft of the plastic slide screw and the motor shaft in place. Set aside, without changing the state of the plastic slide and screw. (illustration)

11. Pull the circuit board and motor from the yellow plastic half and flip upside down. (illustration)

Troubleshooting:

12. Start by examining the solder joints where the wire harness connectors meet the printed circuit board (PCB). I had a cracked joint at pin 7. (illustration)

13. Move on and visually inspect the solder joints for the one microswitch.

14. Use a multimeter and test the one microswitch at the solder joints for correct operation. Usually, only two of the three contacts are used - when the switch is depressed, the two used contacts should have 0 or near 0 resistance (or if your multimeter has continuity checking, it should give a tone). Though usually only the trunk microswitch has a tendency to go bad, this could have occurred here as well. If a switch is bad, you'll need to replace it - there should be a part number somewhere for the switch, if all else fails you can always order a trunk microswitch and mount that.

15. If the switch are good, it's probably a solder joint problem. Heat up the soldering iron and use the desoldering braid to remove all of the solder from every joint in use on the board. Work in sections - remove solder from a few pins, and then resolder the same connections. Removing solder from all of the joints at once from a component will cause it to fall off the board and leave you to realign it. Not difficult, but easy to avoid anyway.

NOTE (Thanks Steve_In_Chicago!): For removing some of the old solder from the solder joints, I recommend picking up a solder-sucker from Radio Shack. They aren't expensive and are a lot easier to use than trying to "wick" off the old solder.

16. The red and blue wires connecting to the other section of the unit are used for a fourth microswitch - it isn't necessary to remove the microswitch from its mounting clip, but do test it as with the others.

Hopefully you've just done something that fixed the problem. Reassemble in the reverse order and see if your door (and wallet) is happy!

SPECIAL REASSEMBLY NOTE – WINDOW PIN INSTALLATION

Re-installing the plastic window retaining pin can be a challenge. There are surely a number of ways to do it. Here are two:

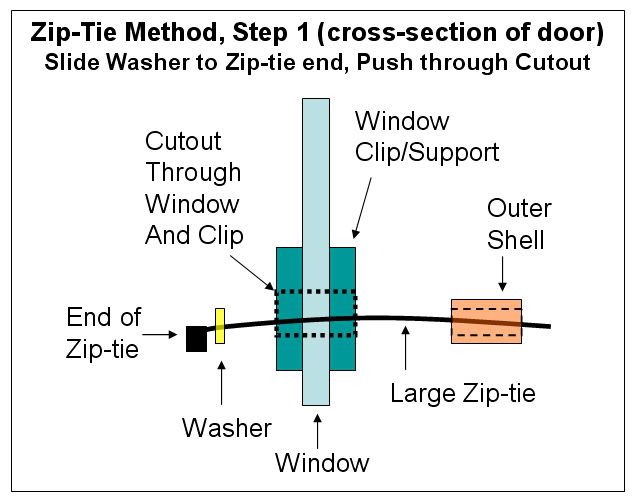

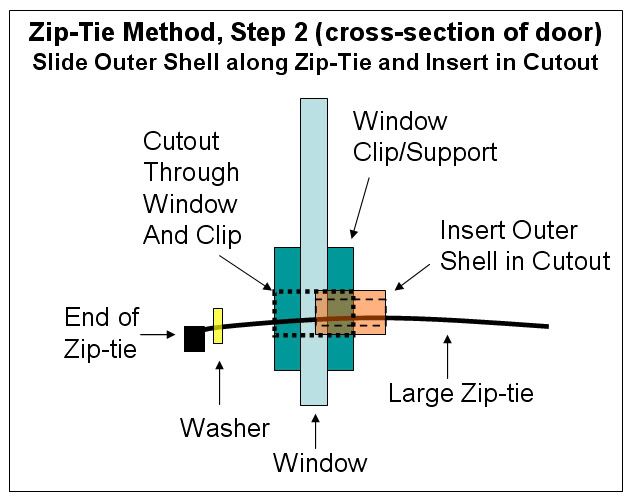

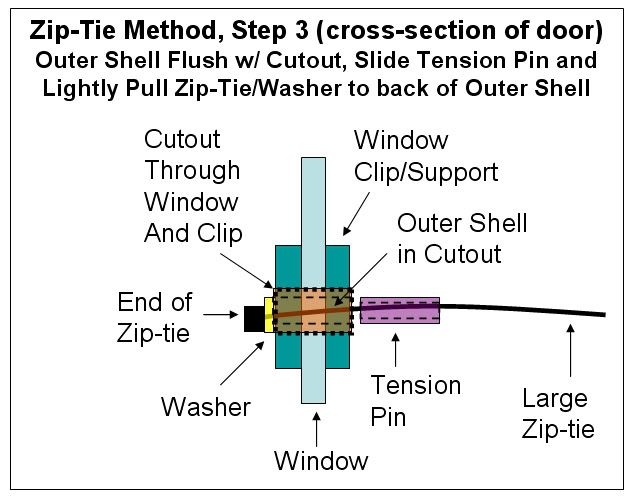

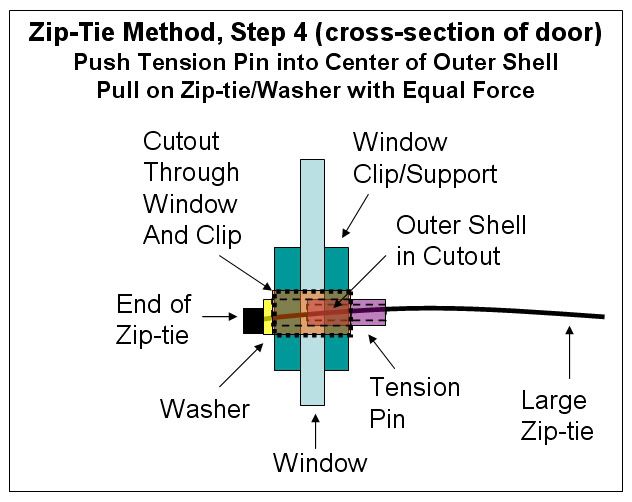

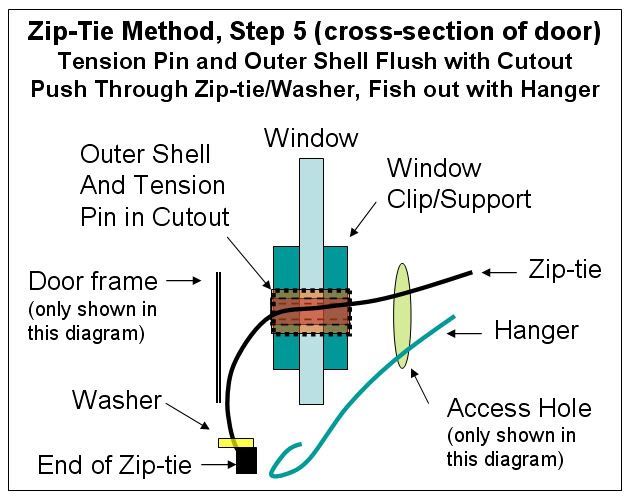

• Zip-tie Homemade Solution:

1. Make sure the glass hole is well lined-up with the hole in the plastic clip (that holds the entire window). You can slightly move/rotate the glass to align them.

2. Next, separate the two donut plastic retaining pins (the ones that fell into the door when removing the window). Determine the easier direction (least force) to insert the tension pin into the larger plastic shell.

3. Take a large zip-tie, and slide an appropriately sized washer or standoff down to the end. The washer’s outer diameter should be slightly less than the window hole’s diameter. The washer’s inside diameter should be sufficiently smaller than the zip-tie end, but big enough to slide onto the zip tie.

4. Now slide the large plastic shell to the end of the zip-tie (up against the washer), taking care that the slot in the shell is facing down (to avoid it dropping off the zip-tie).

5. Insert the end of the zip-tie, and the washer, through the hole in the glass, and then push the outer plastic shell into the hole in the glass. It should be flush with the large plastic clip.

6. Now slide the small plastic tension pin onto the zip-tie, and pushed it up to the outer shell. While pulling with equal force on the zip tie and providing a counter-force with the washer, start pushing on the tension pin. Push until both plastic pins are flush.

7. Now feed the zip tie (with washer) down and behind the window and snag it with a hangar. It’s not the quickest process, but it works if you have patience.

I'm sure this is confusing with a text description, so I whipped up some diagrams to help out:

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

• Factory install (Thanks Old_School!)

1. After sliding the window through the weather stripping, go ahead and place both pins in the window hole and let it rest on top of the window clip.

2. Take a deep breath, and gently (but forcefully) push down on the window. The window clip will spread and the pin will snap into the clip holes as long as it's lined up correctly. Sounds crazy, but it works. I wouldn't do it if it was too cold outside. In fact, the warmer the better. I was told this is how the factory did it. Worked for me as well.

Here is my write-up on fixing an intermittent REAR door lock. The majority of the credit goes to taligentx website and his write-up on fixing the front door lock mechanism. I’d suggest reading his full write-up, and then comparing the two.

http://www.taligentx.com/passat/maintenance/doorlockmechanism/

This procedure is modeled (and partially copied) from taligentx’s instructions. My intent is to bring together all the steps into one clear set of links and instructions. Where the procedures differ only slightly or I’ve put in additional details, it is in bold/red. Other areas are completely different instructions (as noted). I've included pics mostly for those areas not covered in, or different than, taligentx's instructions.

START BY REMOVING THE DOOR PANEL

To start, use this great write-up by captainfantastic to remove the rear door panel:

http://www.passatworld.com/forums/showthread.php?t=263981

I used this write-up, with diagrams, by VAGGuy, to verify the procedure:

http://www.passatworld.com/forums/showthread.php?t=305767

My notes on these steps:

1. The handle cover is attached by three clips. As mentioned in this write-up, it takes quite a bit of force to pry it off (more than I expected). I could easily see this piece breaking if a lot of care is not taken. And please make special care not to damage the upholstery. Put something behind the screw driver or simply pull away rather than leveraging against the upholstery.

2. I did not have a panel separator tool. And I’m guessing 99% of the people who attempt this don’t have one either. I wanted to minimize the chance of breaking the plastic retaining clips. To start, I used a thin flathead screwdriver to slightly pull back a portion of the door panel, and then inserted a puddy knife through the opening. Then I inserted the screwdriver behind the puddy knife (on the metal side) to give it support. I leveraged both and it was very effective at safely separating the clips from the door panel. (picture pending)

3. I found it easier to disconnect the puddle light at the base of the door before disconnecting the cable and window/door electrical harness. It gives you more freedom/access to get the door panel away from the door.

Here is what the door looks like behind the door panel:

WINDOW GLASS REMOVAL

The window removal for the rear door is totally different than the front door. Instead of bolts with retaining clips, there is one plastic retaining “donut”.

1. There is one large rubber circular insert on the metal panel. Remove this. (If you pry with a screwdriver, take care not to damage the mating surfaces.) There is a metal bar behind the hole that has its own access hole.

2. You may need to slightly roll up the window until you can see a donut-like plastic white pin (window retaining pin) through the metal bar access hole. Turn the car key to the On position, and use the driver’s door switch to slowly more up the rear door window. It helps to have a second set of eyes here. (picture pending)

3. Now that you can see the white plastic window retaining pin, you need to pop it out of the window cutout hole. I believe the formal procedure says to first push out the inner plastic tension pin (as confirmed by Steve_In_Chicago), then the larger outer pin. The inner pin expands the outer pin to hold it in place. Use a blunt instrument slightly smaller than the width of the plastic tension pin. Push aside the metal wire for access. Lightly hammer the tension pin to push it out. Be very careful that the hammering instrument doesn't come too close to the sides as it may impact the glass. Also be very careful not to hit the pin too hard and drive it into the outer door (and dent it). Once the inner pin is out, you can push out the outer pin. They will fall down to the bottom of the door. You can retrieve them later when you pull the metal panel off. (In my case, both inner and outer pins were dislodged as one unit.)

This is the pic after the pin has been pushed out:

4. With the plastic pin out, the window will freely move. Carefully slide it up all the way (full up position), and tape it around the top of the door frame (picture pending). I used gorilla tape, but duct tape will probably work just fine. Be careful to protect the top of your door (paint, etc) by putting something like a plastic bag or paper towels between the tape and the non-glass areas. This is another spot where a second set of hands is useful – can’t be too careful with the glass.

UNHOOKING THE LOCK MECHANISM

Note: very similar to front door, except the position of the lock set screw.

1. Pull back the weather trim on the side of the door to expose the lock set screw.

2. Use a Torx T20 driver to partially unscrew the set screw (a few turns at a time). Pull on the exterior door handle - with the door handle in this position, pull on the lock cylinder trim. Keep on unscrewing and testing until the lock cylinder trim loosens and can be removed. NOTE: It is important not to completely unscrew the set screw so as to keep the mounting hardware (behind the door) from falling into the door.

Here is taligentx's pic (note there is only trim, no lock, on the rear door) for this step.

http://www.taligentx.com/passat/images/photo.php?photo=337&exhibition=4&pass=public&lang=eng

3. After removing the lock cylinder trim, you will notice a cable hooked into the side of the exterior door handle. The cable can be positioned (clipped-in) at various points along the handle. Mark the current position by taking a sharpie marker and marking the receptacle (socket) at the end of the cable. Then, prop it loose with a small screwdriver, releasing it from the handle.

4. Use the M8 12 point star driver to remove the two screws, in the door side, that are holding the entire lock mechanism.

REMOVING THE METAL PANEL

1. Disconnect the various wire harnesses on the metal door panel - don't worry about what goes where - each connector can only fit in one and only one place. (picture pending)

2. Use a flathead screwdriver to unclip the various snaps holding the wiring to the panel. It is very easy to break these clips. They may also be brittle from age and heat. I would recommend slightly propping them up with one screwdriver, and using a second screwdriver to try to push in the tabs holding the clips into the metal. Most of my clips broke. To fix them, I bought some generic panel holders and used them with zip-ties to secure the wire harnesses. If you need to replace, try to ensure the new clips are mostly waterproof by using a gasket, sealant or similar. (picture pending)

IMPORTANT ALTERNATIVE OPTION (Thanks Steve_In_Chicago): The black plastic harness holders can be removed without damaging them if you unbolt the metal panel and can get a hand behind it. Use a pliers to squeeze together the little arms holding it into the hole. If you get them squeezed just right, they'll pass through the hole undamaged. Expect to scrape up your arms.

3. Use the 10mm socket to unscrew the seven hex bolts securing the metal panel to the door frame.

4. Pull the panel away from the door frame starting at the edges - if you haven't removed the panel before, the gasket may require a lot of force to pry it away from the frame. Be careful, because the metal can be easily dented by leveraging a screwdriver. Once I finally got a corner of the metal plate starting to separate, my gasket started to pull away from portions of the metal (and stick to the door frame). I used my finger to release the gasket from the door frame and keep it all attached to the metal frame.

5. With the gasket fully separated, the metal panel should be loose. Carefully pull the metal panel down and to the right to allow the attached locking mechanism to clear its corner. Take your time and slowly work it out. Maneuver the entire panel around until the panel is free of the door frame with the lock mechanism and associated wiring attached.

6. Remove the wire harness from the lock mechanism, and push out the rubber gasket (in the metal panel) through which the lock mechanism wire goes through. Pull the wire through the metal panel and remove it - this will allow you to completely separate the metal panel from the door.

REMOVING THE LOCK MECHANISM

1. The lock mechanism is held in place on the metal panel by a plastic bracket with two cylindrical pins keeping the bracket in place.

2. Use a blunt tool to push the pins out from the rear of the panel. (I used the star driver tool as it was just the right size.) My Passat had managed to work the pins loose and dropped them into the door frame, where they've likely lain for months. The bracket had then worked loose of the panel and the entire lock mechanism was free to jostle around in the door. The wiring harness, still being pinned in place, then stressed the electrical connectors internal to the lock mechanism and cracked a solder joint.

3. Unhook the door lock pin rod from the lock mechanism. This may require twisting/spinning the entire lock mechanism to get the best angle to rotate the end of the rod out of the retainer. You will be restricted by the release handle cable. Take your time and avoid rushing and breaking the plastic retainer. (illustration)

4. Remove the interior door release handle cable. Start by popping the harness out of the mount on the locking mechanism. The harness is very securely mounted. I had to use a small screwdriver and leverage from a small gap below the mount to get it to pop out. After releasing the harness, unhook the cable. The cable has to be turned 90 degrees to clear the hole.

5. Separate the locking mechanism from the panel.

LOCK MECHANISM DISASSEMBLY

Note: The lock mechanism repair procedure/description is the same as the front door, except for only one microswitch on the circuit board itself. Follow taligentx’s instructions. I’ve edited/annotated a few areas (in bold).

1. Use a Torx T10 driver to unscrew the 5 visible Torx screws (four on the face, one on the side). (illustration)

2. Pull the plastic bracket's long clip from the mechanism - there is a sixth screw hidden underneath.

3. Use a Torx T20 to remove the large Torx screw.

4. You should now be able to carefully pull apart the two sections of the mechanism - you'll need to unclip the plastic snaps while pulling the sections away from each other. (illustration)

5. After pulling these sections away, the last Torx T10 screw will be revealed. Remove it.

6. Flip the mechanism to the yellow plastic side. Pull and remove the spring indicated. NOTE: Be sure to note the orientation of this spring. (illustration)

7. Pull the metal handle indicated upward to allow separation of the two halves.

8. Flip to the black plastic side without allowing the two halves to separate.

9. The internals of the mechanism are mounted on the yellow plastic half - carefully pull up on the black plastic half to reveal the electronics inside. (illustration)

Locking Mechanism Diagnosis:

The electronics are straightforward. There is only one microswitch for the rear door. This microswitch, next to the white plastic slide, determines the current state of the door lock. The motor actuates electronic locking and unlocking.

Note: Take care not to change the position of the various handles and slides - it's fairly easy to determine how the different switches and handles interact with each other when it's time to put things back together, but it's easier to leave everything in the positions discovered. Also, note the position of the brown gear on the motor shaft to the small white attachment mounted inside. To be safe, I used a sharpie marker to mark the positions of the wheels (relative to each other) and the position of the white plastic slide (relative to the housing). There is an alignment between the notch in the copper track inside the brown gear and a metal cylinder in the white plastic container. Just be sure to reset this relationship during reassembly.

10. Pull the white slide from the assembly, along with the white mount holding the shaft of the plastic slide screw and the motor shaft in place. Set aside, without changing the state of the plastic slide and screw. (illustration)

11. Pull the circuit board and motor from the yellow plastic half and flip upside down. (illustration)

Troubleshooting:

12. Start by examining the solder joints where the wire harness connectors meet the printed circuit board (PCB). I had a cracked joint at pin 7. (illustration)

13. Move on and visually inspect the solder joints for the one microswitch.

14. Use a multimeter and test the one microswitch at the solder joints for correct operation. Usually, only two of the three contacts are used - when the switch is depressed, the two used contacts should have 0 or near 0 resistance (or if your multimeter has continuity checking, it should give a tone). Though usually only the trunk microswitch has a tendency to go bad, this could have occurred here as well. If a switch is bad, you'll need to replace it - there should be a part number somewhere for the switch, if all else fails you can always order a trunk microswitch and mount that.

15. If the switch are good, it's probably a solder joint problem. Heat up the soldering iron and use the desoldering braid to remove all of the solder from every joint in use on the board. Work in sections - remove solder from a few pins, and then resolder the same connections. Removing solder from all of the joints at once from a component will cause it to fall off the board and leave you to realign it. Not difficult, but easy to avoid anyway.

NOTE (Thanks Steve_In_Chicago!): For removing some of the old solder from the solder joints, I recommend picking up a solder-sucker from Radio Shack. They aren't expensive and are a lot easier to use than trying to "wick" off the old solder.

16. The red and blue wires connecting to the other section of the unit are used for a fourth microswitch - it isn't necessary to remove the microswitch from its mounting clip, but do test it as with the others.

Hopefully you've just done something that fixed the problem. Reassemble in the reverse order and see if your door (and wallet) is happy!

SPECIAL REASSEMBLY NOTE – WINDOW PIN INSTALLATION

Re-installing the plastic window retaining pin can be a challenge. There are surely a number of ways to do it. Here are two:

• Zip-tie Homemade Solution:

1. Make sure the glass hole is well lined-up with the hole in the plastic clip (that holds the entire window). You can slightly move/rotate the glass to align them.

2. Next, separate the two donut plastic retaining pins (the ones that fell into the door when removing the window). Determine the easier direction (least force) to insert the tension pin into the larger plastic shell.

3. Take a large zip-tie, and slide an appropriately sized washer or standoff down to the end. The washer’s outer diameter should be slightly less than the window hole’s diameter. The washer’s inside diameter should be sufficiently smaller than the zip-tie end, but big enough to slide onto the zip tie.

4. Now slide the large plastic shell to the end of the zip-tie (up against the washer), taking care that the slot in the shell is facing down (to avoid it dropping off the zip-tie).

5. Insert the end of the zip-tie, and the washer, through the hole in the glass, and then push the outer plastic shell into the hole in the glass. It should be flush with the large plastic clip.

6. Now slide the small plastic tension pin onto the zip-tie, and pushed it up to the outer shell. While pulling with equal force on the zip tie and providing a counter-force with the washer, start pushing on the tension pin. Push until both plastic pins are flush.

7. Now feed the zip tie (with washer) down and behind the window and snag it with a hangar. It’s not the quickest process, but it works if you have patience.

I'm sure this is confusing with a text description, so I whipped up some diagrams to help out:

• Factory install (Thanks Old_School!)

1. After sliding the window through the weather stripping, go ahead and place both pins in the window hole and let it rest on top of the window clip.

2. Take a deep breath, and gently (but forcefully) push down on the window. The window clip will spread and the pin will snap into the clip holes as long as it's lined up correctly. Sounds crazy, but it works. I wouldn't do it if it was too cold outside. In fact, the warmer the better. I was told this is how the factory did it. Worked for me as well.