Standard disclaimer applies. Post for information only. Repair your Passat at your own risk Symptom: =========== Coolant flange is made of plastic. It locate at the back of engine and can be felt but not seen. It has (a) CTS (coolant temperature sensor) on top (b) connected to engine block on front (c) connected to heater core inlet hose below tilting toward the back (d) connected to the rigid coolant pipe which routes directly above the intake manifold. If you are new to it, use your hand to follow the heater core inlet hose (located in the plenum chamber, the one to the driver side) until it reaches engine block The o-ring seals become less effective when aged. A week after doing some work for my PCV system on 2001 AUG engine, I started to notice missing coolant about 300~400 mL. it seems to only leak when engine/coolant is at certain temperate point or pressure point. One day after a short drive I notice leakage underneath.

![Image]()

Leakage from coolant flange should only goes to the passenger side, e.g, dripping off front differential on auto tranny (although parking on a slope with belly pan on could drip coolant on the driver side as well). Coolant might not drip much when you park your car. In addition unlike oil, coolant dries up. Look down to the back of engine from passenger side, you might find white/pink stain below. Feel the heater core inlet hose and the flange itself, you might catch it wet (coolant feel more like soapy water, i.e. not oily; however it is not uncommon for CVG and CCA gasket to leak oil onto the flange). In retrospect, I wiggle the rigid upper coolant hose a slight bit during PCV work. That, combined with some oil residual from oil cooler failure years ago, caused one or more of my o-ring sealer to leak intermittently. Reference: ========= (1) Inspired by doyles-1.8T (Coolant leak - pics inside, pls advise if it's the flange?) (2) Thanks to PZ for sharing his advice and set of pictures. I hope that this write-up will help other beginners like myself. Caution: ========= (1) You will touch catalyst converter and your body/arm/hand will be wrapping all around the engine. It is recommended to wait for the car to cool off (2 hours or more). (2) Try not to drop parts/tools in that engine back area. Although often you may find them on the ground, it take hours or forever never to find when not. (3) Coolant flange takes only 4 bolts to install but one could end up spending hours just to put one particular bolt on so allow enough time and don’t stress out. When stuck, take a step back; go get a drink– to avoid repetitive strain injury/overstretch. (4) It is said that AWM is worse than the AUG, “the later the model, the worse it gets. Even the 01.5 AWM is not as bad as the 04 AWM”. You coolant flange setup could well be different from mine. If you got stuck, you may want to  Bob the Builder “we can do it” if that helps with your mental sanity. (5) Some coolant will leak to the ground and make work area slippery. dry it up or try not to slip&fall. Time budget =========== Gurus might do it within 3 hours. Don’t know how many hours a shop might charge. I budgeted for a day. It ended up being 3 hours in the morning and 5 hours in the afternoon, which include a couple of hours trying to figure out what to do with the heat core inlet hose o-ring (see discussion below). I worked really slow to make sure I get it right, and took many breaks. I think I could do it in about 4 hours tomorrow, and due to memory loss, 5 hours next year. Parts: ======= Coolant flange (my local dealership typically has all these in stock) AEB/ATW: 058 121 132 AUG/AWM: 058 121 132 A (superseded by 058 121 132 C) note that both A & C has 058 121 132 B imprinted on the plastic body. The guy in the Parts room said that the part # imprint is only for the plastic piece and the VW part number covers the plastic, one o-ring and some metal inserts so I cannot go by the imprint. AUG/AWM’s flange needs three o-rings beside one o-ring which is included on the flange. O-ring for upper coolant pipe: 058 121 687 (size 31.5 x 3.65) O-ring for CTS: N 903 168 02 (size: 19.6 x 3.6) O-ring for heater core inlet hose: not show in PW ETKA or my local dealer’s ETKA. Its ID (I guess the inner diameter should be around 22 ~ 22.5). Above CTS o-ring will not fit as shown in picture below (new CTS o-ring to the left, old inlet hose o-ring to the right which is in relatively good shape)

Bob the Builder “we can do it” if that helps with your mental sanity. (5) Some coolant will leak to the ground and make work area slippery. dry it up or try not to slip&fall. Time budget =========== Gurus might do it within 3 hours. Don’t know how many hours a shop might charge. I budgeted for a day. It ended up being 3 hours in the morning and 5 hours in the afternoon, which include a couple of hours trying to figure out what to do with the heat core inlet hose o-ring (see discussion below). I worked really slow to make sure I get it right, and took many breaks. I think I could do it in about 4 hours tomorrow, and due to memory loss, 5 hours next year. Parts: ======= Coolant flange (my local dealership typically has all these in stock) AEB/ATW: 058 121 132 AUG/AWM: 058 121 132 A (superseded by 058 121 132 C) note that both A & C has 058 121 132 B imprinted on the plastic body. The guy in the Parts room said that the part # imprint is only for the plastic piece and the VW part number covers the plastic, one o-ring and some metal inserts so I cannot go by the imprint. AUG/AWM’s flange needs three o-rings beside one o-ring which is included on the flange. O-ring for upper coolant pipe: 058 121 687 (size 31.5 x 3.65) O-ring for CTS: N 903 168 02 (size: 19.6 x 3.6) O-ring for heater core inlet hose: not show in PW ETKA or my local dealer’s ETKA. Its ID (I guess the inner diameter should be around 22 ~ 22.5). Above CTS o-ring will not fit as shown in picture below (new CTS o-ring to the left, old inlet hose o-ring to the right which is in relatively good shape)

![Image]()

My inlet hose o-ring is in best shape comparing to my other o-rings so I end up reusing mine. Please let me know if someone figures out a part number or exact size. I read that AEB/ATW’s flange supposedly has one extra port and has a cap and maybe an extra o-ring. Not sure though. Optional CTS retaining spring: 032 121 142 (I replaced mine, it is plastic and mine is a little bit bent). G12+ coolant, depending on how much you already and plan to loose. AUG engine has a fill capacity of 7L (3.5L coolant + 3.5L water) which is needed when doing a flush and refill. I only top off lost fluid and add 1L (0.5L coolant + 0.5L distilled water) Tools: ========== Just need 8mm, 10mm, 13mm socket & 6mm hex key, and may a short 10mm combination wrench, various wrench extension and adapters. Inspection mirror to view obstructed area is imperative, you need it more so when putting bolts back. Optional: hose and container to collect used coolant; compact light source; compact digital camera for views from where your hands can go but eyes not. Procedure: ============ (0) Leave Passat on ground (no jackstands or ramps unless you are super tall); belly pan can be removed but does not really mater unless you have a habit to drop stuff down there; disconnect battery is optional (disconnect at negative terminal). Older engine like my AUG is not picky about losing battery connection so I did. Unscrew three bolts holding the coolant reservoir and disconnect the sensor on the bottom of it. Move the reservoir out of way (probably leave it on top of your power steering fluid reservoir). You might also want some padding or pillow to make yourself more comfortable. You will work a lot with your left arm down between engine and air box, and your left hand working behind the engine.

![Image]()

(1) Drain and save pink G12+ coolant Open coolant reservoir cap to allow air to go in. Access the drain port via the driver side lower grill by “gently” pulling on the driver side edge

![Image]()

The drain valve can be turned by a large screw driver. The drain port is pointing to the driver side (I connect an orange color hose to it). Tip: soak the hose end in hot water to make it soft will facilitate the connection

![Image]()

![Image]()

Close the drain valve. You can remove your drain hose and put back the grill now or later. (2) Real work starts. Pull out the CTS by first remove the clip. You could see the edge of the clip and insert a small screw driver will help you to pull it toward the back.

![Image]()

Spring clip removed

![Image]()

Pull CTS upward

![Image]()

I further disconnect the electrical socket so I can clean CTS properly (this o-ring is the worst among all, mushy and sticky)

![Image]()

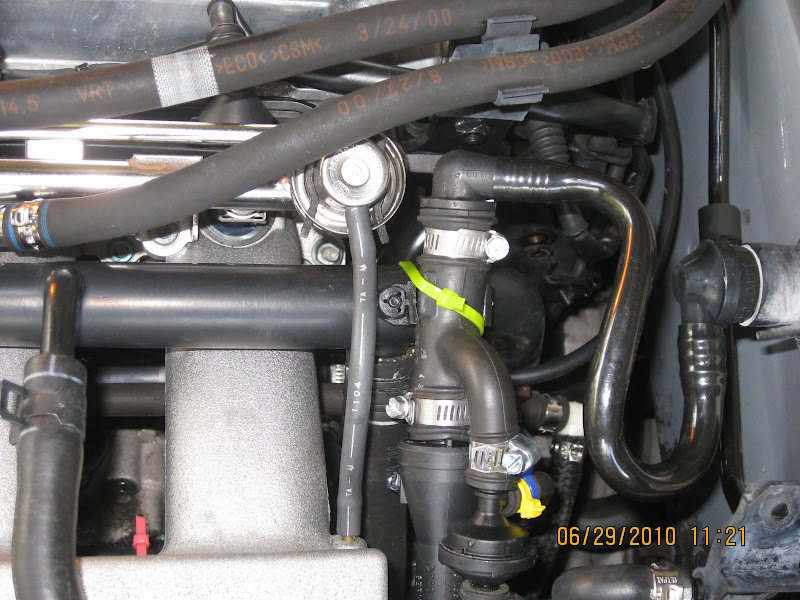

(3) Remove two 10mm bolts connecting upper coolant pipe to the flange. Working from driver side and use some wobble extension. This step is easy.

![Image]()

loosen one 10mm bolts holding upper coolant pipe next to the frontmost intake spoke.

![Image]()

I broke a plastic bracket in my past “gentle” work which is replaced by a green zip tie below, now I just cut it to allow some movement for upper coolant pipe.

![Image]()

(4) Remove lower flange bolt. This is the Fun step. You will retrieve your prize at the end of it (regular socket will do, you don’t have to use deep wall socket).

![Image]()

But first, you need to identify the shiny thin turbo oil line above the catalyst converter. On AUG/AWG engine, it is held on to the stud part of above bolt by another 10mm nut. Inspect it using your mirror. The image shows the line at the back (nut and flange were already removed).

![Image]()

Turbo oil line and heat shield above CAT

![Image]()

On the AWM engine, it is easier to remove the Kombi valve to access the bolts and studs holding the flange on the engine. I also remove the metal PCV pipe (on the exhaust side) from the top Y hose on the valve cover. This allows easy access to both bolts.

To remove the valve, you use a 5MM allen wrench on the 3 bolts. They are easy to feel. Be careful not to drop the metal gasket from between the valve and head. It may be stuck on the valve itself.

You will also need to replace the front hose attaching the pipe to the up-pipe of the air pump as it will snap when moved. Leave the rear hose attached. Part number/cost from ECS:

Air Pump Hose

Mfg#: 058133785B~MTC

$9.76

This saves a lot of time and trouble when replacing the flange.

Free the line/heat shield assembly by removing a. two 6mm hex sockets bolts toward lower edge of heat shield b. two 8mm regular bolts (each 8mm bolt has two washers). c. on the back of the engine, remove one 10 mm nut d. move out and down the turbo line and remove the bolt of interest (I basically now put my skinny arm between the heat shield and engine block and wrap around to reach the bolt) (5) Now the upper flange bolt. I worked from the driver side, the space allows for a short 10mm combination wrench to turn the nut 30 degree at a time. The bolt is holding down a bracket of a short rigid crankcase ventilation pipe onto the flange and then onto the engine block – understanding this would help when moving the flange away from the block or during installation. Picture below show the bracket on top left corner (I have no control of focus given the near nonexistent space).

![Image]()

Once the nut is loose, you might get your fingers in from somewhere to retrieve the bolt and not drop it because 30 degree at a time would take forever. (6) Heater core inlet hose. First slide flange toward passenger side and toward back (remember to push turbo oil line out). At this point the flange is only connected to the inlet hose. I took a picture to see other pipes/wirings in that neighborhood.

![Image]()

Then carefully wiggle and move the flange toward below, back and driver side until you get it next to the oil filter.

![Image]()

Remove the metal spring clip and disconnect the hose by pulling each other away. (no twist and turn here to get the hose off as there are tabs underneath to provide correct installation orientation). I appreciate the spacious room here – less chance of bruise or cut when ages-old connection suddenly comes loose. Take a moment to make sure you got the correct part (mistake happens)

![Image]()

My old flange has no crack, but for the reason that its design does not hold the engine block o-ring securely, I would not reuse it. (plus mine is 9+ years old)

![Image]()

The key to a successful installation is to absolutely make sure each and every o-ring stay where they should be. I might reuse and return the new part back to my local dealership if I have following design on my flange.

![Image]()

edited: another important thing as PZ kindly points out - "clean the back of the head before replacing the flange... Any dried coolant left there will cause the new seal to leak". I used a piece of lint-free cloth to clean the area and inspect it carefully before proceeding to installation. If required, you could use fine grit sandpaper and give it a quick cleaning as PZ suggested. Installation is the reverse of removal but since in this job it probably will take longer so I spell it out for mental comfort. (7) If you get a new inlet hose o-ring, remove the old o-ring, and seat the new one inside the hose. Wet o-ring with diluted had dishwasher detergent/soapy water (or for that matter just G12+) would help installation. Push new flange into inlet hose. Secure with its metal spring clip. Unless you are able to do flange swap in place, wiggle coolant flange back to its neighborhood pay attending to your specific piping / wiring arrangement. My inlet hose goes below the yellow wiring

![Image]()

(8) Wet and put o-ring over the rigid upper coolant pipe. Review comment and picture in step 5 above. Get flange to seat flush on the engine block and push two together to seal the connection. This way if the o-ring is not seat correctly, it will be push out and you can see and feel it. put on both 10mm bolts there loosely, as long as the o-ring is kept inside the connection. You want those bolts a bit loose for jiggling the flange in following step. (9) Install the lower flange bolt. This step take anywhere between minutes and hours depend on luck, karma or alignment of planets. Remember to push away the turbo line, use your inspection mirror to help jiggling and alignment. The bolt has a flat tip (instead of slight tapered tip of other bolts) which is really a pain. If your luck is not so much in your favor, using your right hand to pull the flange away from the block for ~1mm might improve the six sense of your left hand, which is holding the bolt and trying to thread onto engine block. If succeeded, snug tight (I mean, still allow room to jiggle). (10) Now the upper flange bolt. It is easier now since the alignment is nearly in place if not perfect. It helps that this bolt has a normal tapered tip. The challenge is how to deliver it. I end up use electrical tape to hold it on to my 10mm deep wall socket and deliver it using my left hand. Outside wrapping for better friction.

![Image]()

Hand tight this bolt as much as possible. Remaining will be easy. Use your sockets/wrench to tighten all the bolts now, total 4 bolts on the coolant flange and 1 bolt for upper coolant pip near the front intake spoke. (11) Wet new CTS o-ring, seat it on the CTS, connect it to the electrical socket, insert CTS into the flange port, secure it with plastic spring clip. (12) Now secure the turbo line/head shied, in this order: the 10mm nut over lower flange bolt, two 6mm socket head bolt, two 8mm bolt with washers. Get all the bolts/nuts on before final tightening Review your notes during remove process to make sure you covered any extra things you have removed. (13) Finally fill up and bleed the coolant system. Identify the heater core outlet hose which has a bleed hole marked on top of the hose.

![Image]()

Use channel pliers to loosen the spring clamp and use your other hand to move hose out to the extent that bleed hole is off the connector.

![Image]()

In case you like to have more space for your hand to move the outlet hose. You can unbolt a 13mm bolt to the passenger side of the battery and remove the clamping plate and then slide the battery toward the passenger side.

![Image]()

Set coolant reservoir on top of intake manifold to gain height.

![Image]()

If you are reusing your G12+ coolant, add some type of filter to your funnel (I used coffee filter paper, which is a bit too slow for flow but that is the only thing I have around; since the debris are at the bottom of my bottle, I ended up only filtering my used coolant when I was close to the bottom my bottle.) Mix new G12+ with water at a ratio of 1:1 (unless you drive in some extremely cold weather). Refill until coolant seeps out of the bleed hole. At that point, reconnect the outlet hose securely. Lower coolant reservoir to its own seat. Fill coolant reservoir to spec. Close the cap. Don’t forget to connect the sensor at the bottom of coolant reservoir. Take care of battery clamp and negative terminal if you touched it. You can take a test drive now and recheck the coolant level upon return. If bleeding is done right, coolant level should still be within spec though it could drop a little bit. If it drops below MIN line, just fill it up. Turn the cap very slowly to release the pressure gradually when coolant is hot (or you can just wait for it to cool down). This should be it. All comments, correction or advice are welcome.

On the AWM engine, it is easier to remove the Kombi valve to access the bolts and studs holding the flange on the engine. I also remove the metal PCV pipe (on the exhaust side) from the top Y hose on the valve cover. This allows easy access to both bolts.

To remove the valve, you use a 5MM allen wrench on the 3 bolts. They are easy to feel. Be careful not to drop the metal gasket from between the valve and head. It may be stuck on the valve itself.

You will also need to replace the front hose attaching the pipe to the up-pipe of the air pump as it will snap when moved. Leave the rear hose attached. Part number/cost from ECS:

Air Pump Hose

Mfg#: 058133785B~MTC

$9.76

This saves a lot of time and trouble when replacing the flange.

Free the line/heat shield assembly by removing a. two 6mm hex sockets bolts toward lower edge of heat shield b. two 8mm regular bolts (each 8mm bolt has two washers). c. on the back of the engine, remove one 10 mm nut d. move out and down the turbo line and remove the bolt of interest (I basically now put my skinny arm between the heat shield and engine block and wrap around to reach the bolt) (5) Now the upper flange bolt. I worked from the driver side, the space allows for a short 10mm combination wrench to turn the nut 30 degree at a time. The bolt is holding down a bracket of a short rigid crankcase ventilation pipe onto the flange and then onto the engine block – understanding this would help when moving the flange away from the block or during installation. Picture below show the bracket on top left corner (I have no control of focus given the near nonexistent space).